Before we get started – let’s define a Brenton Audit. During an audit, a Brenton Representative will visit your facility, inspect your Brenton or Currie equipment and provide a detailed service report including recommendations for replacement parts or upgrades to increase efficiencies and reduce downtime.

Your equipment does not have to be down for the audit to be completed and the results of the audit will be provided within two weeks of the visit. These results are guaranteed to improve OEE and help present future downtime.

Audit results vary from customer to customer/solution to solution. On a recent visit to a long-time food manufacturer customer, Brenton audited 5 case packers – some of these case packers were in production and some of them were down. The results displayed easy-to-repair areas of the machines that experience day-to-day wear.

Belt Wear Spots

On many of the machines – there were several instances of worn belting. One included a belt and pulley combo. They were so worn that the pulleys almost jumped out each time the mechanism was moving.

Another area of wear that was documented included the belt teeth. The drive shafts are timed together, so when the belt jumps a tooth the two shafts get out of time.

Worn Con Rods

The con rods transfer movement between two points, and as you see in this video that slop in the con rod caused a change in the intended movement. These types of wear cause parts to be out of position or timing. This eventually results in a machine crash.

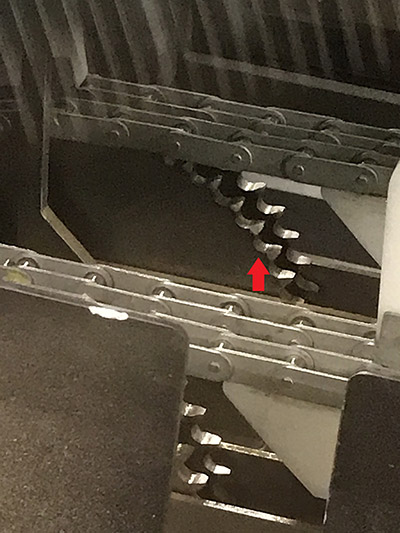

Sprockets

Sprockets on the machines with teeth worn to a point.

Flap Catching

One of the machine product loaders was catching on the flap openers on its way out of the case. Overtime a pain point like this can cause a major crash.

All of these finds and more helped the customer better plan their maintenance and reduce their downtime. Additionally, since Brenton was completing the audit, the maintenance techs were able to keep the plant running. Bringing in a fresh set of eyes to help work through challenges, seeing issues we know to look for and documenting customer modifications to the machines all allow for improved OEE and future service.

Our customer’s span beyond the United States and our audit offerings does as well. Feedback from a valued Canadian customer and his experience with this program:

I was quite impressed by the service offered by Brenton. When I first received the email to book a free on site visit I did not think that it would apply to across the border customers. I was surprised when my email was followed it up with a scheduled visit to our facility. Tyler arrived on time and spent the day with our equipment and our maintenance team to make sure everything was looked after. His visit was followed up with a report and a detailed parts list was delivered shortly after. It was an unexpected service which was greatly appreciated. It is not very often that we get a OEM supplier to offer a free site visit especially on equipment that is 15+ years old. Brenton has always had timely service and the parts department has always been quick to help out. Thank you for providing this extra service and exceptional continued customer support.

Are you interested in scheduling your Brenton audit? Please visit our registration page today!