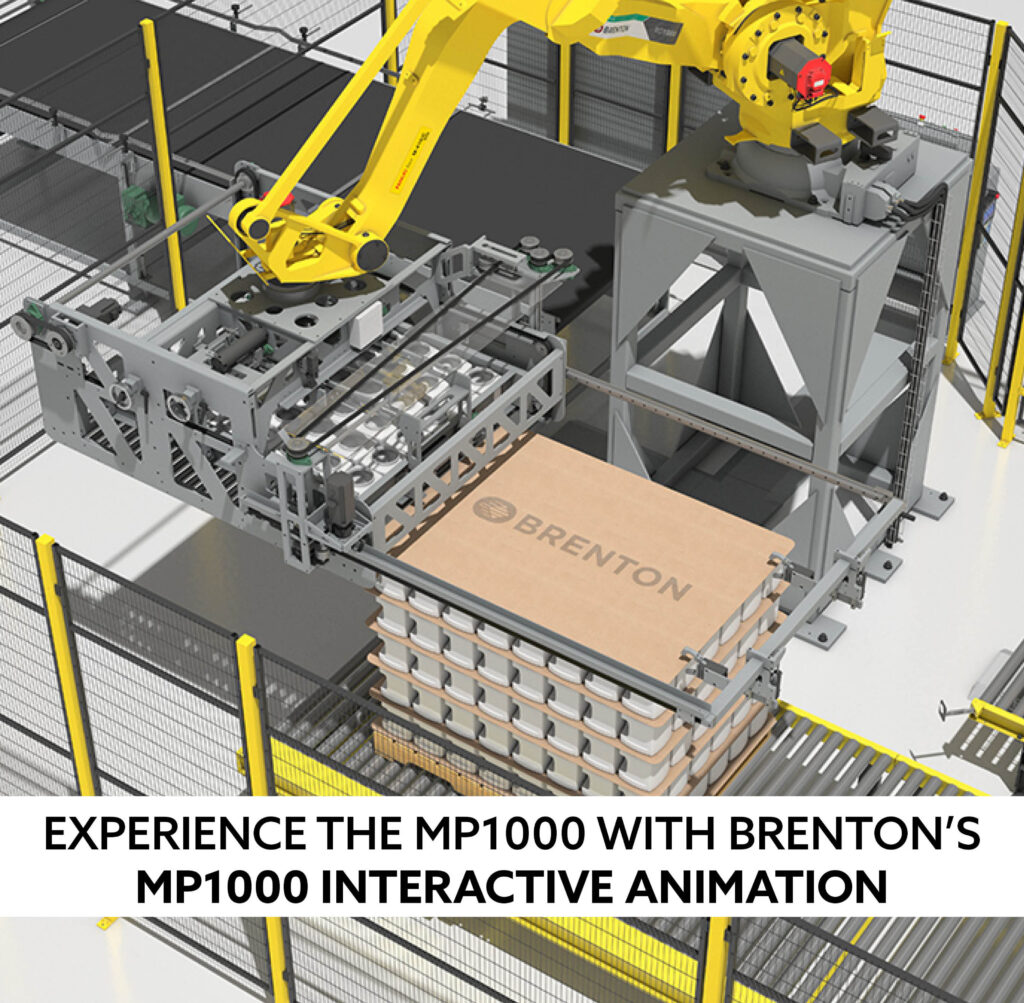

Staring at an 8-foot mountain of palletized peanut butter jars without the proper equipment to depalletize it can make disassembly seem like an impossible task, but luckily Brenton has the solution. The MasterPal MP1000 Palletizing/Depalletizing End of Arm Tool can gently pick up and move full layers of product at a time for quick and easy pallet construction and deconstruction. The MP1000 is easily adjustable between pallet sizes, making it the Swiss Army knife of end of arm tooling for bulk material handling.

Through the “cradle and place” method, the MP1000 combines a servo-operated rotary tool and slat system to gently handle full layers of product weighing up to 500 pounds with each motion, and it can stack pallets up to 102” with consistent, tight layers. The machine works well in a variety of industries, especially those with irregularly shaped packs and bottles. Food products, particularly challenging ones such as coffee creamer, benefit from the soft touch and four-sided handling that ensures minimal damage to the packaging while loading and unloading. The MP1000 eliminates product handling limitations created by rollers or vacuum pick and place which leave trays behind or fail to handle certain bulk items.

Another premier benefit of the MP1000 is automatic changeover, which allows it to switch from 48”x40” pallets to 56”x44” pallets quickly and without the need for hands-on adjustments. This flexibility saves time and ensures accuracy whether you’re stocking snacks or compartmentalizing condiments. The added bonus of proven longevity allows continued use over several years without the need for time-consuming maintenance or machine downtime.

When it comes to palletizing or depalletizing, remember…you have a pal in Brenton.